PRODUCTS

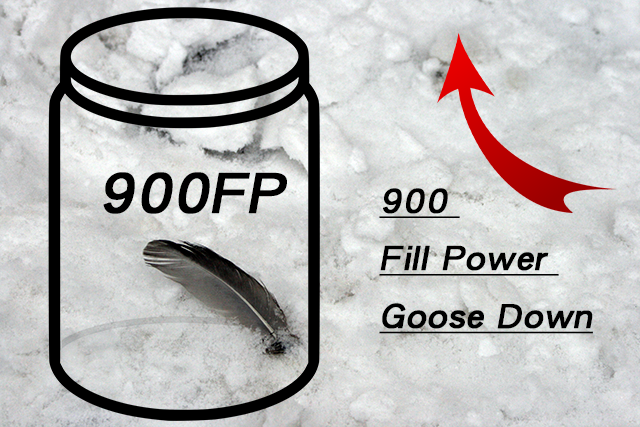

900 Filling Power Down: The higher filling power captures more volume, and provide more warm than other lower filling power down. This quality is supply few months only in a year.

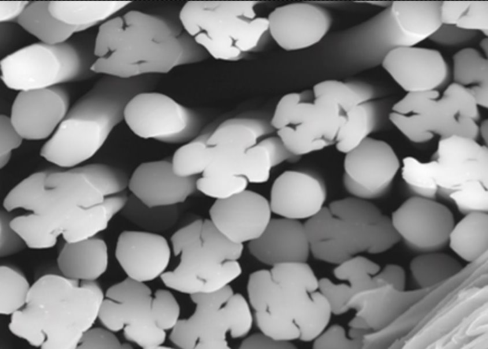

Grapes Down: It named as like a bunch of grapes. This down are extremely warm, due to, the down interlock together by natural and kept air inside. It makes down products warm, but, less volume. This product suitable for extreme outdoor activity that requires in warm, light weight, and easy moving. However, this down need manual and supply is limited. Please inquire early.

| 1. | DWR Down:“Durable Water Resistance Down”. It is suitable for high quality sleeping bags and outwears to keep the down dry, avoid the moisture and wet to reducing body temperature. This product had been researched and developed yearly, and applies nanotechnology to create the most effective water resistant down in the market. |

| 2. | Anti-Microbial Down: It suitable for hospital or other special requirement. The products can be washed and reduced 99% of microbial that other products. |

| 3. | Colored Down: It meet fashion and warm together. |

| 4. | High performance proprietary synthetic fiber and down blend: It reduces static electricity. The synthetic fiber can treat with the infrared to fast increasing body heat. |

Recycled Down: Keep warming & sustainable

Using recycled down as an opportunity not only to extend the lifecycle of the material, but to transform waste into supply chain, being ethical and eco-friendly. Base on sustainable environment vision, renown brands have developed using recycled down in their high-end winter clothes. The perks of using recycled down make both economic and environmental.

Quality

Quality is our best representatives, especially, the Filling Power and Cleanness.

| 1. | The high filling power provides warmer than low filling power, and insulate less down in down products. We have various grades from 500 to 1000 filling power. |

| 2. | Cleanness is defined by turbidity and oxygen number. Turbidity inspects the dust contain and impurity. The higher turbidity is less dust and impurity. As IDFB regulation, the minimum requirement is 300mm. It can be claims as Super Clean or Hypo-Allergenic when higher than 500mm. Our products are higher than 500mm as super clean. |

| 3. | Oxygen number: Down come from geese and ducks construct by protein, like human hair. The lower number means more clean. The industry requires to be less 10. Our internal requirement is less 5 to provide best quality to consumers. |

Technology:

| The procedures for turbidity are: | |

| 1. | Mix 10 grams down & feather with 1 liter of distilled water in a 2 liter jar. |

| 2. | Agitate jar until material begins to soak the water. |

| 3. | Put it on Horizontal shaker for 90 spm for 15 minutes shaking time. |

| 4. | Strain water from jar through a mesh (size 200) into a beaker. |

| 5. | Transfer water slowly into the turbidity tube. The turbidity tube has “+” mark on the button. |

| 6. | Identify the exact point where the “+” mark is no longer visible. |

| 7. | Read the scale markings representing the mm of liquid in the tube. |

The procedures of Filling Power are:

| 1. | Put 35g sample in a box size 40cm x 40cm x 40cm. |

| 2. | With steam condition 20 sec. in 4 sides, and blowing to make it dry (it simulate with human micro-environment). |

| 3. | Move 30g sample into the cylinder, put disk on top on sample. The measure is the filling power volume in cubic inch per 30g. |